Basic knowledge and application of hot melt adhesive film

Release time: 2025-03-17

1. What is Hot Melt Adhesive Film?

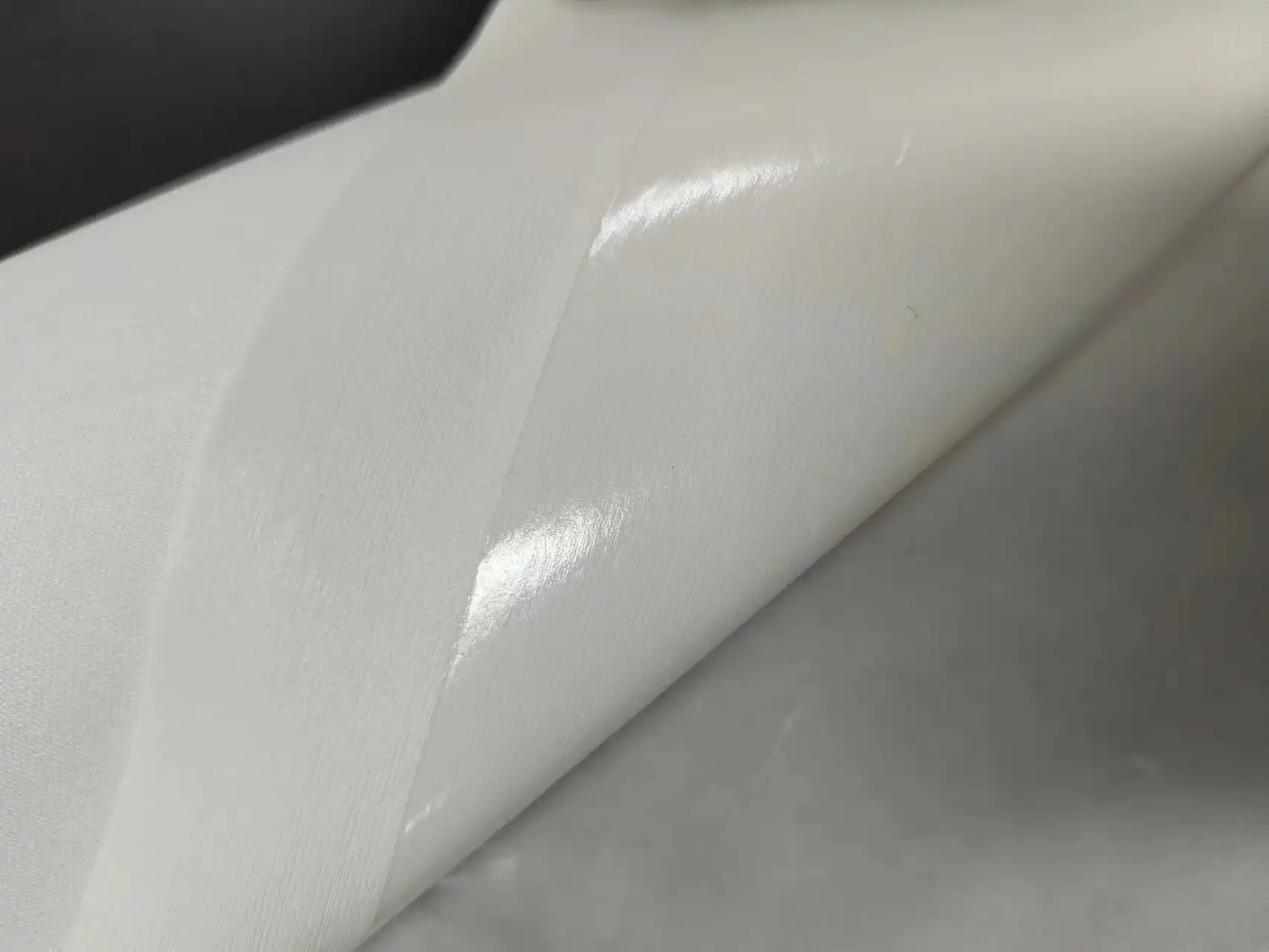

Hot melt adhesive film is a thin, sheet-like material that is typically used by heating. When heated to a certain temperature, it becomes sticky and can bond with other materials. After cooling down, it hardens and holds things together firmly. Unlike liquid glue, this film is cleaner to use eco-friendly and doesn’t release harmful gases.

2. Characteristics of Hot Melt Adhesive Film

Fast Bonding: It only needs a brief heating to soften and bond quickly.

Environmentally Friendly: Unlike traditional adhesives that require solvents, thermoplastic hot melt adhesive films does not need solvents, making it safer for the environment.

Strong Bond: Once cooled, the bond is firm and long-lasting.

3. Applications of Hot Melt Adhesive Film

(1)Apparel and Textiles

In the fashion industry, hot melt adhesive films are used for seamless clothing designs, offering a comfortable and perfect fit without the need for traditional stitching.

(2)Automotive Industry

Hot melt adhesive films are used in car manufacturing, such as for securing seat upholstery, dashboards, and reducing noise and vibration. They are also used to secure exterior components like lighting fixtures and windows.

(3)Electronics

In electronic products like smartphones and televisions, hot melt adhesive films are often used to secure components or batteries. They help prevent small parts inside the device from moving, enhancing the stability of the product.

(4)Furniture Industry

Hot melt adhesives are used in assembling furniture components like frames, drawers, and cabinet doors. They offer a simple and efficient method of securing parts, especially on production lines requiring fast assembly. In the production of upholstered furniture (such as sofas and chairs) and leather furniture, PA hot melt adhesives are commonly used to attach leather or fabric to the frame, offering increased production efficiency.

(5)Metal Industry

Hot melt adhesives provide strong adhesion when bonding metal to materials like plastic, glass, or other substances, especially in industries such as automotive and home appliances. And can be used for surface treatments of metal parts, such as edge sealing or coating protection, to prevent corrosion or wear on metal surfaces.

In conclusion, high-performance hot melt adhesive films are a versatile and efficient solution across various industries. With their fast curing, strong adhesion, and environmental benefits, they are essential in applications like packaging, automotive, electronics, and textiles. As technology advances, their demand will continue to grow, making them a key material for modern manufacturing processes.